The neural network project was sponsored by ARPA to determine the feasibility of

using artificial intelligence to compensate for thermally induced machining errors.

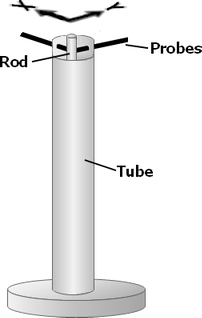

The test setup consisted of a 30 inch copper tube affixed with a couple dozen thermocouples.

Fiber optic non-contact probes measured the displacement of the tube relative to

a fixed Invar rod while being randomly heated by computer controlled industrial heat

guns. The displacement and temperatures were used to train a 3 layer back propagation

neural network and the same network was then used to predict future displacements

under similar conditions. The same concept was then used to outfit a CNC lathe and

the machining errors were predicted as a function of the temperature profile of the

lathe. The network was able to correctly predict errors in both setups to about

a 95% accuracy.