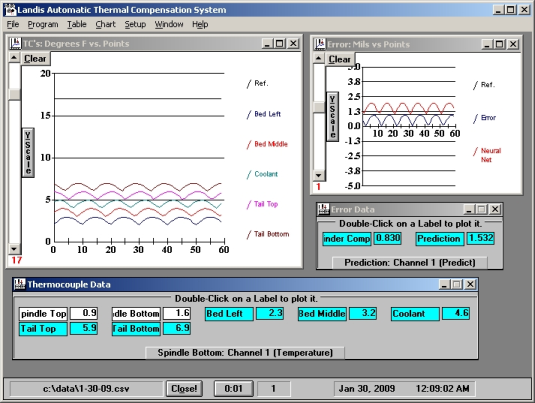

This project was a closed-

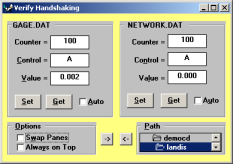

The program incorporated a neural network to train on a data set, and after training

it communicated with the CNC controller to compensate for the errors in real time.

The system was able to reduce dimensional errors during machine warm up from several

thousands of an inch to a few tenth of thousands of an inch.